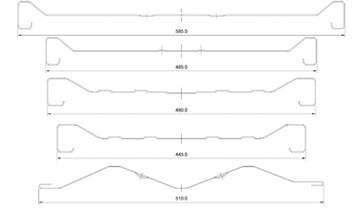

COLLECTING ELECTRODES

Cold Roll Formed Electrostatic Precipitators (ESP) Collecting Electrodes are roll-formed from CRCA sheets andcorrosion resistant Corten. These sections are used as dust collecting equipment for major pollution control applications in power plants, cement industries, paper and sugar industries, etc. These profiles are supplied in standard lengths as per customer design and packed in steel crates with application of rust-preventive oil. We supply our Collecting Electrodes in different profiles like 400, 420, 445, 480, 485, 500, 585, 700, 720 & ZT-24 (510 width) etc and of required length. These Collecting Electrodes are manufactured with high precision, which make them extremely reliable and offer trouble free operation.

DISCHARGE ELECTRODES

Discharge Electrodes / Emitting Electrodes is the heart of Electrostatic Precipitator. The Discharge Electrodes emit charging ions that generate an electrical field between the discharge electrodes and the collecting plates. The electrical field forces dust particles in the gas stream to migrate toward the collecting plates. The particles then precipitate onto the collecting plates, which is dislodged by rapping. These electrodes are superior to all other designs as they havelow corona onset voltage and are not affected by the dust load and type of dust. The ESP Electrodes offered by us, are made up of the finest components, under the strict supervision of industry leading experts. Moreover, our ESP Electrodes are available at affordable prices, with no compromise on quality

ESP INTERNAL COMPONENTS

Auro is positioned among the leading manufacturers and suppliers of ESP Internal Components. We have carved out a niche for ourselves in the industry by offering innovative products at affordable prices.We use premium grade raw materials and a very efficient manufacturing technology, which ensures only quality ESP components &spares are used by our clientele. We also offer customized ESP internal components to suitably address our clients’ requirements.

ELECTRO-MAGNETIC RAPPERS

Electromagnetic rappers are an electromagnetic device with the plunger being the only moving part. The vertical configuration is supported from the precipitator roof, eliminating rebound related failures and maximizing acceleration response to the electrode system. Our EM rappers are NOMEX insulated, and the coils are vacuum impregnated as opposed to traditional manual varnishing. We provide –

For Top Rapping – Rapper Coils (110V/220V), and its complete assembly with Plunger, Boot Seals, Rain Hood etc.

We also provide Tumbling Hammer rapping mechanisms – Geared Motor along with Gearbox Rapper Shafts, Drive Bearings, Inner Arm, Outer Arm, Hammers etc as per client design.

SUPPORT, SHAFT & HOLLOW BUSHING

The Porcelain Bushing for ESP covered by this instruction are divided into the following types according to their functions (all of which we supply) –

Porcelain Hollow Bushing: Hollow Bushing is the insulation part used in the electrical systems, and support the integral structure of discharge electrode.

Post Bushing: Their function is to rigid support for discharge electrode framework and make it insulation against ground.

Shaft Bushing: The shaft bushing is the insulation part used in the electrical systems, and transmission the torque, mechanical vibration or rigid impulse of discharge electrode.

Wall Bushing: The wall bushing is used on transmission high voltage wore or conductive rod and make it insulation against ground.

SILO MANUFACTURING

We provide powerful silo solutions for customers in major industries around the globe. Our expertise has been recognized by operators, engineering contractors, consultancy agencies and material handling engineers within the power, chemistry and agriculture industries.Three types of silos are in widespread use today: tower silos, bunker silos, and bag silos. At Auro, we predominantly use steel panels to fabricate silos.

TANK FABRICATION

Fabrication of quality tank metal structures demand high quality materials. Auro has achieved that by implementing the system of incoming test (initial check) of material used in fabrication. We use only technical norms and conditions compliant raw materials, and strictly adhere to state regulations and project documentation compliance for each tank commissioned.

DUCT FABRICATION

Duct fabrication is simply the manufacture and production of customized parts for the HVAC system of a building. Duct fabrication requires the precise cutting and bending of sheet metal into desired cylindrical or rectangular shapes. We provide normal and vapour piping duct solutions for our clients. We provide high quality ducts at affordable prices.